Manufacturing LED Screens with Reliable Quality: The TQL Process

As technology advances, LED screens have become an integral part of everyday life, from advertising displays to entertainment. However, with a wide variety of LED screens flooding the market, it's difficult to determine which products meet quality standards. Impactrum recognized this problem and created the Trusted Quality LED screen (TQL) process to set industry manufacturing standards.

Lack of LED screen certification

Currently, there are no certifications on the market that specifically identify and verify the quality of LED screens. While there are certifications for some components used in screens, such as LED chips, there is no standardized process to ensure the overall quality of the finished product. This lack of certification makes it difficult for consumers to be sure which products are meeting high quality standards, which can make it difficult to ensure the quality of the product and reduce its reliability.

Establish a TQL process

To address this issue, Impactrum established the TQL process, which aims to set quality standards for LED screens, covering all aspects from component selection to manufacturing and quality control.

Impactrum creates a comprehensive process to ensure that your product meets certain standards.

The TQL process is composed of three parts.

λ Component selection During the component selection process, Impactrum establishes and selects criteria for the components used to make LED screens, ensuring that only the highest quality components are sourced.

Β Manufacturing standards Manufacturing standards focus on making screens with precision and care, following established protocols to create the best product possible.

③Quality standards : Finally, the quality standards component ensures that the finished product meets or exceeds certain performance standards.

Impactrum's Manufacturing Standards

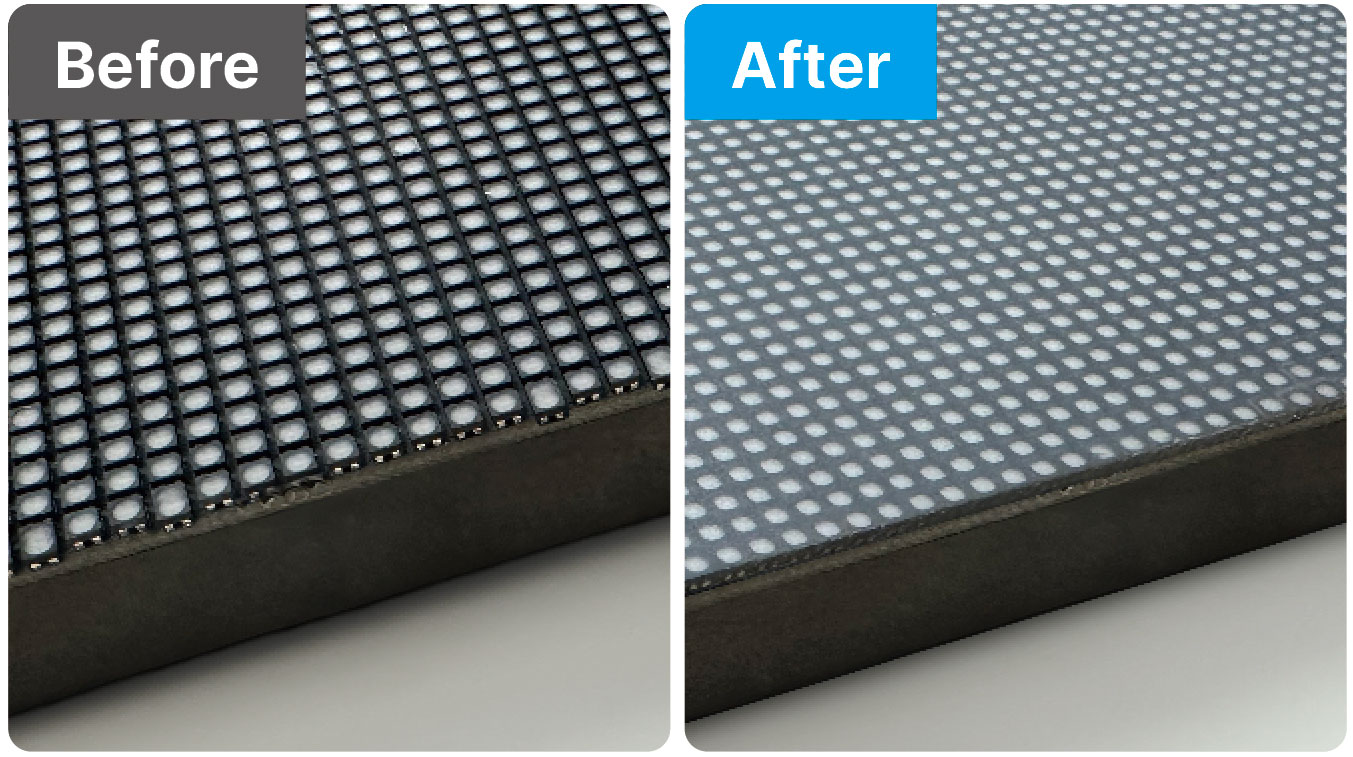

Flatness

It undergoes its own flatness test to reduce display distortion and improve viewing experience.

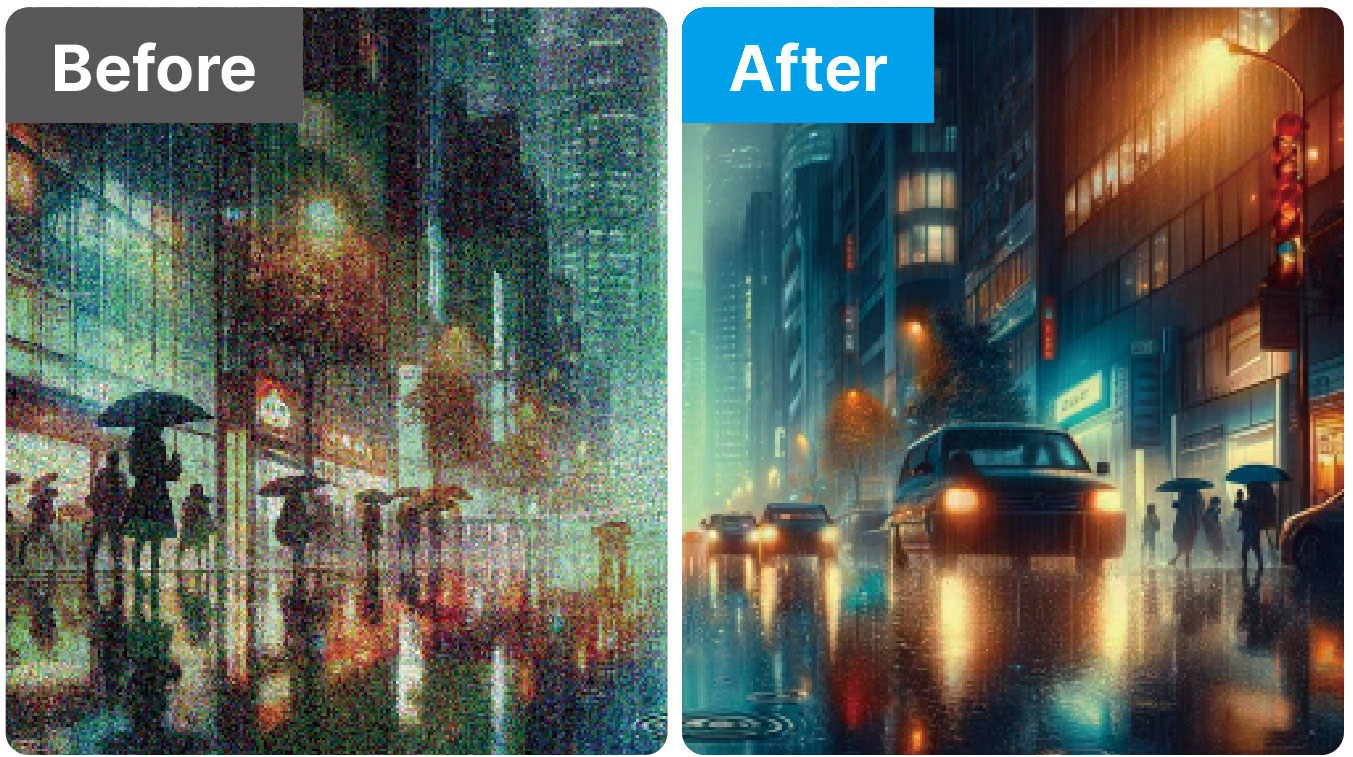

Color

RGB color adjustment ensures that all the colors in your content are fully represented.

Calibration

Shape

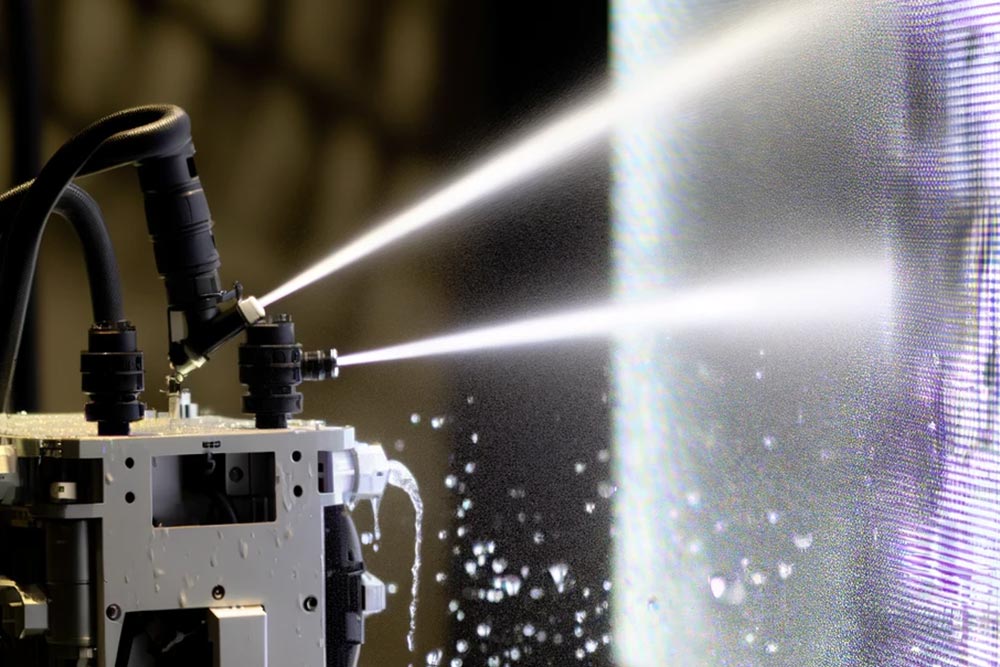

Waterproof

Protection